- English

Air Throw, the distance along the axes of a fan impeller where the air speed of the stream gets a defined value, usually 1 m/s or 0,5 m/s. Spread, the width of the air stream cone at air throw distance (both vertically and horizontally), is its complementary concept. Unfortunately, air throw is not so easy to measure, air stream is not always as laminar as we would wish.

Talking “Controlled-environment Agriculture” (CEA), we aim for an ecosystem recreating the right conditions to achieve the maximum potential of a crop. Forced ventilation systems that guarantee the ventilation rate and the homogenisation of the interior air, independently of outside conditions, are a must. ASABE1 defines ventilation rate as the volume of air exchanged per unit of time per unit of floor area. The recommendations are at least 45 to 60 renewals per hour.

But renewal, whatever its rate, does not guarantee an even environment inside the greenhouse. This is achieved by air circulation: moving or mixing air to control temperature, humidity and CO2 distribution. The most effective way to achieve that even environment is the horizontal circulation. Here, the air throw at 1 m/s indicates the maximum overlapping distance between two circulating fans in the same row to keep up continuity and the good mixing ratio.

For some crops air movement in between the leaves is appreciated; in this case counting on reliable values for fans air throw is crucial too, although now the speed to achieve the desired positive effects is < 0,5 m/s.

Now, how maximizing and then assuring that correct air throw?

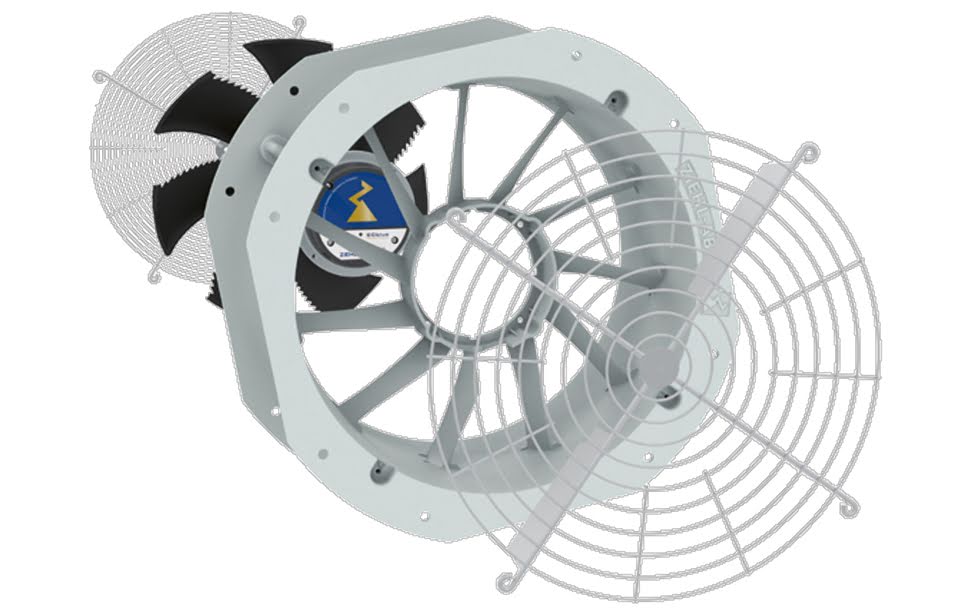

Answering the first question, ZIEHL-ABEGG combines two dedicated accessories:

• Built-in composite guide vanes pushing in the air further at given speed.

• Powder coated cross-grill, enhancing that air throw.

There is only one response to the second matter: choosing a trustworthy partner for your greenhouse.