- English

In the previous newsletter of this magazine, we introduced the history of the fiberizing technologies within ANDRITZ. This time we want to provide more insight into the Pressafiner Technology.

Pressafiner – FROM THE PAST…

The Pressafiner is a machine that belongs to the broad family of compression devices, largely used in panelboard and pulp & paper plants and also in new modern ANDRITZ processes like for example the bioethanol production and the recycling of MDF boards.

Well-known in the sectors can be mentioned the following devices: Plug Screw Feeder, MSD (modular screw device), Pressafiner (for fiberizing) and Impressafiner (for fiberizing and additional impregnation).

ANDRITZ owns an extensive knowledge on these machines and can design and customize fiberizing devices according to the demands, supporting the customers for all process and maintenance related topics.

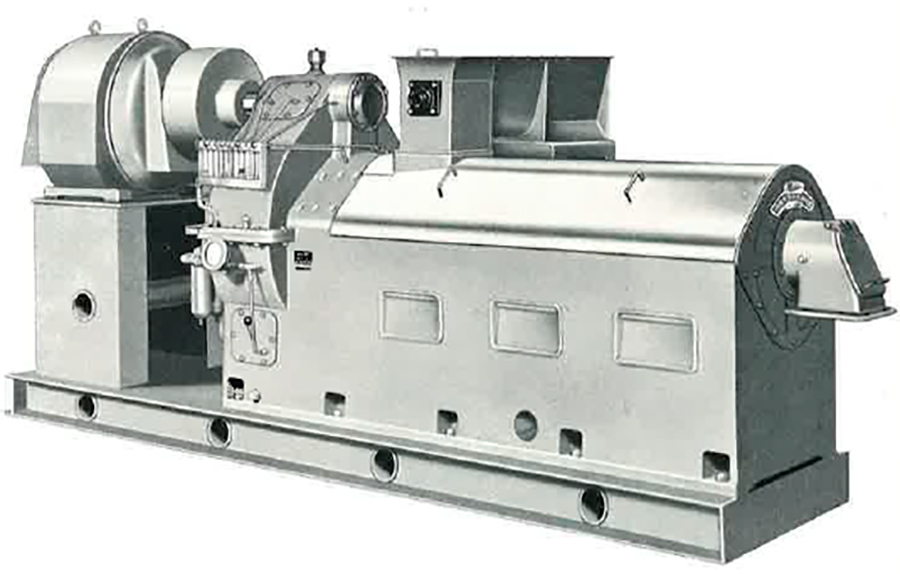

Pressafiner – original machine by Bauer Bros. Co., later ANDRITZ

One important question is now: why did we choose the Pressafiner Technology for the substrate industry, together with the Refiner Technology, even if also other technologies to fiberize the wood like hammer mills or extruders were available in ANDRITZ?

Pressafiner Technology… FOR THE FUTURE

The Pressafiner Technology has extraordinary technical features and offers several benefits, some of them come from our new developments.

Key points:

All this said, we believe that the Pressafiner Technology will be the game-changer in the substrate industry for the future.

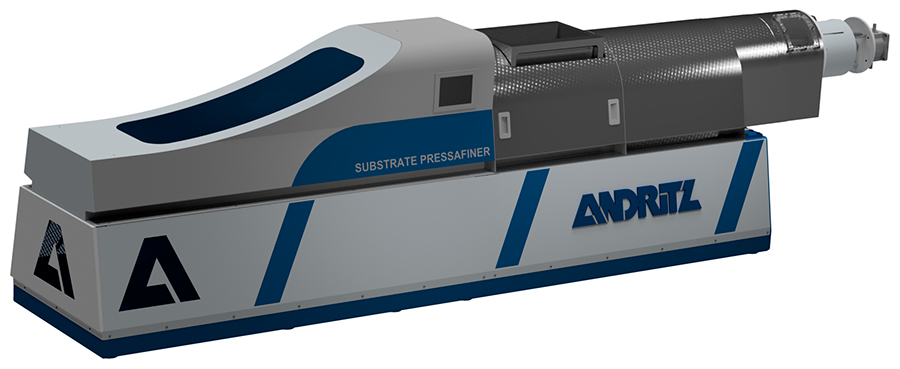

Substrate Pressafiner. NOW! AT THE EXPO 2025

The Substrate Pressafiner has been expressly developed now for the substrate industry to process wood chips from all sorts of wood and in all kinds of typologies: virgin wood, recycled wood, oversize wood from compost and wood residuals of different origins as well.

Additional raw materials like wood bark, miscanthus, bamboo and other non-wood plants can also be fiberized, according to customer´s demands.

The recently developed Substrate Pressafiner SP300 model was awarded with the selection for the Innovation Lab Austria for the EXPO 2025 in Japan and represents already a real innovation for the substrate industry.

See link: https://www.expoaustria.at/en/pavilion/innovation-lab-austria/innovationdetails/221/

Substrate Pressafiner SP300 – quarter section – new development by ANDRITZ

Enrico Fuser

Senior Sales Manager, Wood Fiber Substrate