- English

Refining is a key mechanical process in both the Pulp & Paper and Panelboard industries, playing a decisive role in determining the quality and performance of the final product.

The main objective of refining in papermaking is to enhance the physical properties of pulp fibers to improve paper quality. In panelboard applications—especially MDF (Medium-Density Fiberboard) production—refining is used to mechanically defibrate wood chips into fine, uniform fibers suitable for forming dense, smooth, and high-strength boards.

Among the most widely used refining systems are disc refiners, which employ rotating plates to apply controlled shear and compression forces. This article explores the fundamentals of refining technology, with a focus on its purpose, working principles, and the role of equipment manufacturers like ANDRITZ, whose durable and efficient refiners have left a lasting legacy in wood and pulp processing.

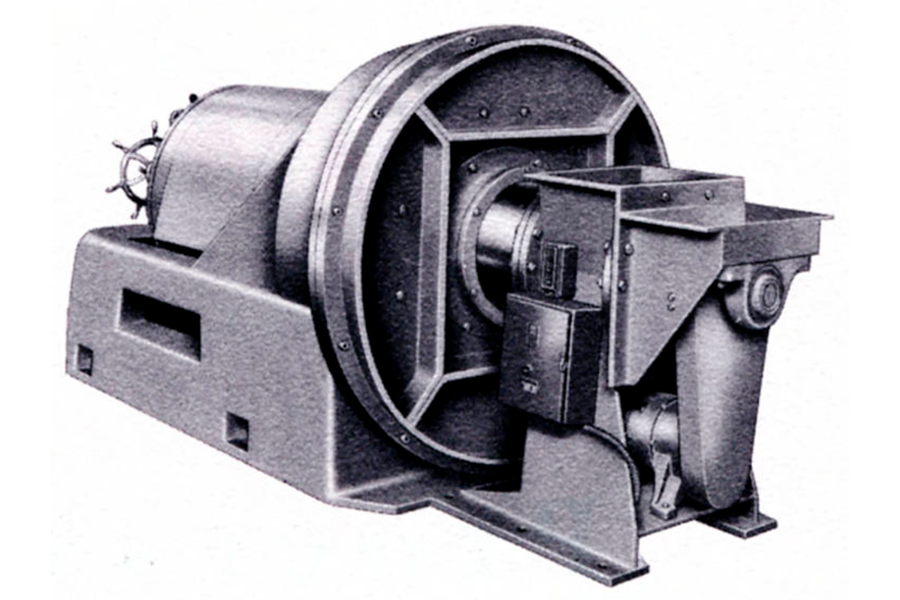

A Strong Legacy in the ANDRITZ Portfolio

Single Disc Refiner – From Bauer Bros. Co. to ANDRITZ

The single disc refiner has long been a cornerstone of fiber preparation—whether in the Pulp & Paper industry or in Panelboard production. Though used in different contexts, the principle remains the same – mechanical defibration through rotating and stationary discs. The difference lies in the input material, process conditions, and intended output.

In the Pulp & Paper industry single disc refiners are used to mechanically treat the pulp by applying shear and compression forces. This process increases fiber flexibility, promotes fibrillation, and improves inter-fiber bonding, leading to stronger and more uniform paper sheets.

In the Panelboard industry single disc refiners are used to convert pre-steamed wood chips into fine, uniform fibers through thermomechanical refining. Operating under high temperature and pressure, these refiners break down chips into individual fibers with properties optimized for board strength and smoothness.

Regardless of application, single disc refiners are valued in both industries for their efficiency, adjustability, and critical role in determining final product quality. Their versatility and mechanical robustness make them a backbone of fiber preparation processes across a wide range of manufacturing operations.

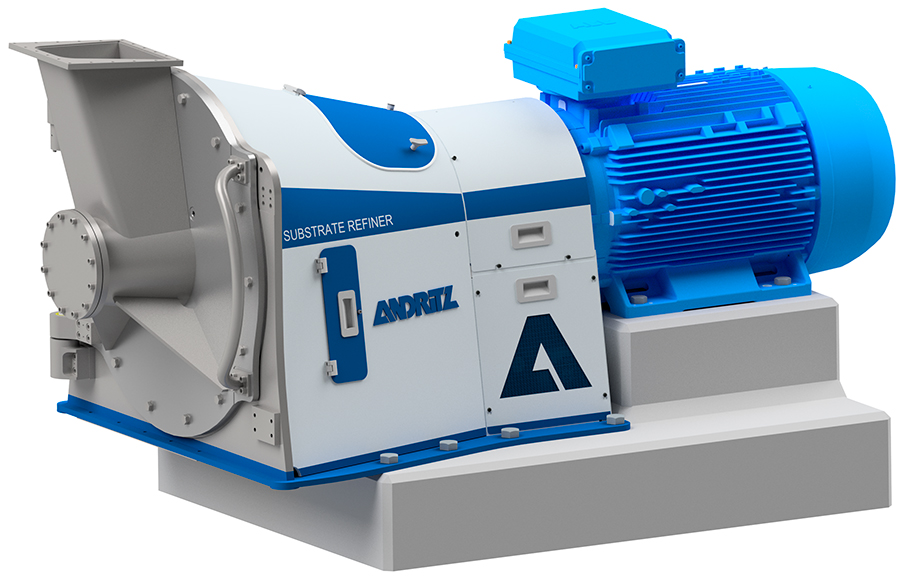

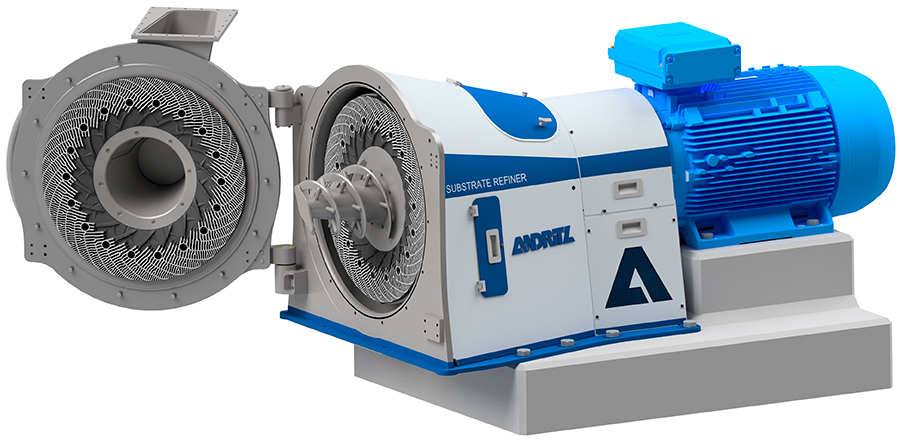

Extensive Know-how Meets a New Market: Introducing the Substrate Refiner

In response to evolving resource challenges and increasing demand for sustainable fiber solutions, ANDRITZ has developed the Substrate Refiner—an innovative system specifically designed for the substrate industry.

The Substrate Refiner applies decades of refining expertise to a new purpose: processing wood chips into tailored fibers suitable for horticultural substrates and various industrial applications—efficiently, flexibly, and sustainably.

Key Functions:

Benefits:

The Substrate Refiner on the Global Stage: EXPO 2025

The newly developed Substrate Refiner, SR-38 has been selected for the prestigious Innovation Lab Austria at EXPO 2025 in Japan—a recognition of its relevance and potential in shaping the future of sustainable fiber processing.

Link: https://www.expoaustria.at/en/pavilion/innovation-lab-austria/innovationdetails/221/

Substrate Refiner, SR-38 – New Development by ANDRITZ

Conclusion: Refining Yesterday, Today, and Tomorrow

From historical innovations like the Bauer Bros. single disc refiner to modern breakthroughs like the Substrate Refiner, ANDRITZ continues to bridge tradition and technology. With a focus on sustainability, energy efficiency, and precision, ANDRITZ refining solutions are ready to meet the challenges of tomorrow—across industries and around the globe.

Christoph Leitner

Sales Manager, Wood Fiber Substrate

For information: www.andritz.com/wood-fiber-substrate