- English

Since this article is the first for the ‘Wood Fiber Substrate’ team of ANDRITZ in this journal, we would like to start with the background story, as is often done in movies.

Whether the title of this story refers to the fibers for substrates or the origins of ANDRITZ is left to the reader’s discretion.

ANDRITZ History

Parts of Andritz traces its existence to the merger of two similar engineering/manufacturing companies, Sprout-Waldron and The Bauer Bros. Co., ultimately purchased by Andritz AG in 1990.

Sprout-Waldron traces its founding to 1866. The company soon entered the feed milling business and eventually developed an extensive product offering for the agriculture, industrial, and pulp & paper markets.

Bauer Bros. Co. was founded in Springfield, Ohio in 1878, and like Sprout-Waldron, initially manufactured agricultural equipment (corn grinding and harvesting equipment) and eventually entered the pulp and paper markets. Later on, these companies were merged to Sprout-Bauer.

Andritz AG is headquartered in Graz, Austria, and has served the process, resource recovery, and pulp and paper industries internationally since 1852. The acquisition of Sprout-Bauer enhanced Andritz AG position in these markets, particularly pulp and paper, since Sprout-Bauer was a primary supplier of equipment to this market.

We are proud of our long history and strong commitment to serve our customers.

Refining History

The first refiner-like equipment that was fiberizing wood, was developed by a company in 1859. It was called “raffineur” and it was initially equipped with sandstone discs.

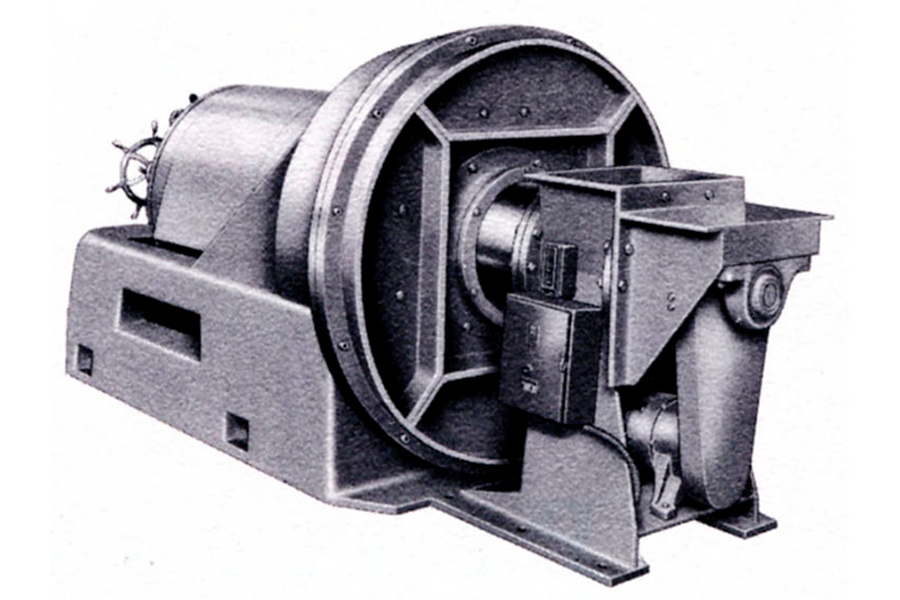

During the 1950’s the first attempts were made to utilize refiners for production of newsprint. At an early stage, Bauer Bros. Co. developed double disc refiners equipped with two counter rotating metal discs, later there were single disc refiners developed by Sprout Waldron and others.

In the beginning, refiners for paper production were atmospheric until pressurized chip refiners were introduced. Specific paper properties were improved compared with atmospheric refining. Process and control systems for refiners improved considerably during decades.

Today, most installed refiners are used in applications within the panelboard and pulp & paper industry.

Single Disc Refiner – original machine by Bauer Bros. Co.

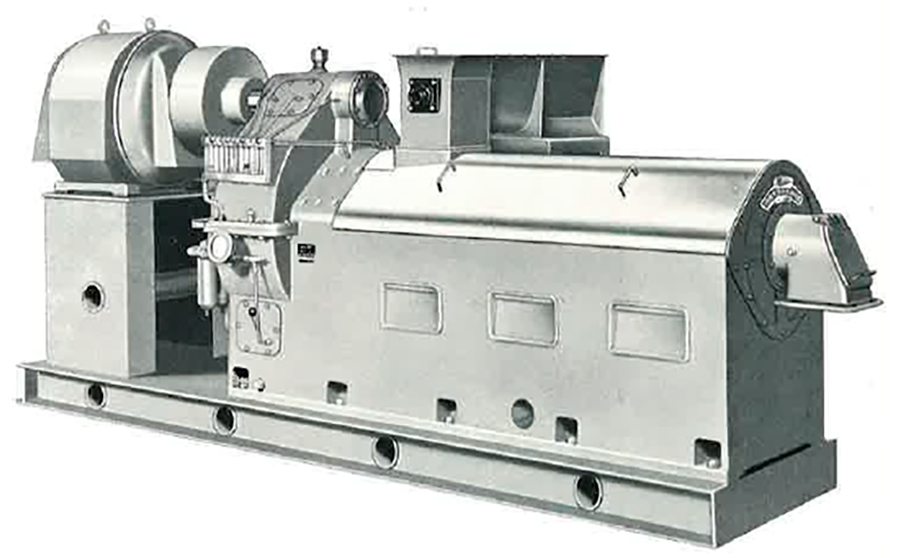

Pressafiner History

In the early atmospheric Refining processes, refining was performed after wood chip pretreatment in a Pressafiner. The task of the Pressafiner at that time was to dewater wood chips or rather to feed them to the refiner with a more or less constant moisture content.

However, it was recognized early, that the heavy-duty Pressafiner machines could also break up wood chips.

Pressafiner – original machine by Bauer Bros. Co.

Wood Fiber Substrate Story

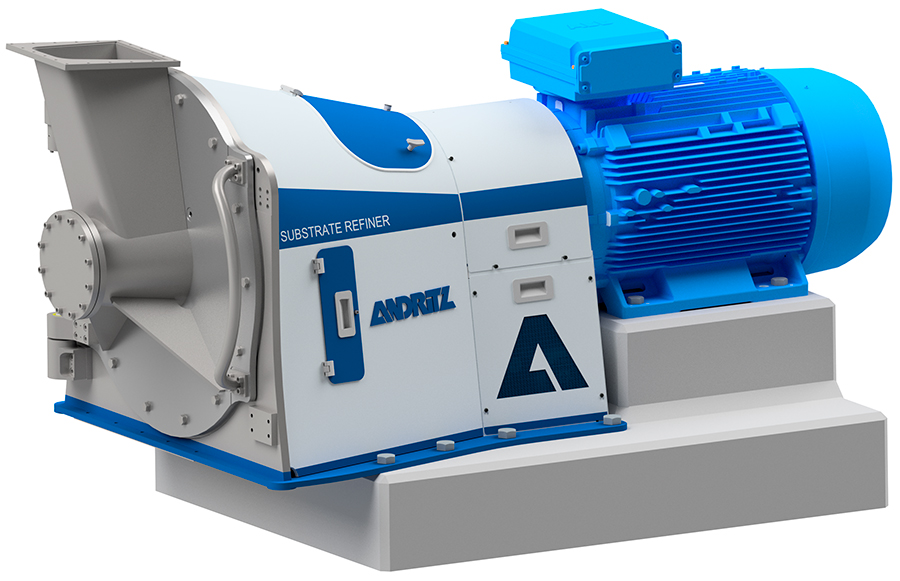

We at the Wood Fiber Substrate Team have taken a step back, looked at the history, and adapted today’s advanced fiberizing technology to produce fiber substrates.

We rely on the latest refiner model on the market, the Substrate Refiner SR-38, which can produce the desired fiber structure from various organic materials under atmospheric conditions.

Substrate Refiner SR-38 – new development by ANDRITZ

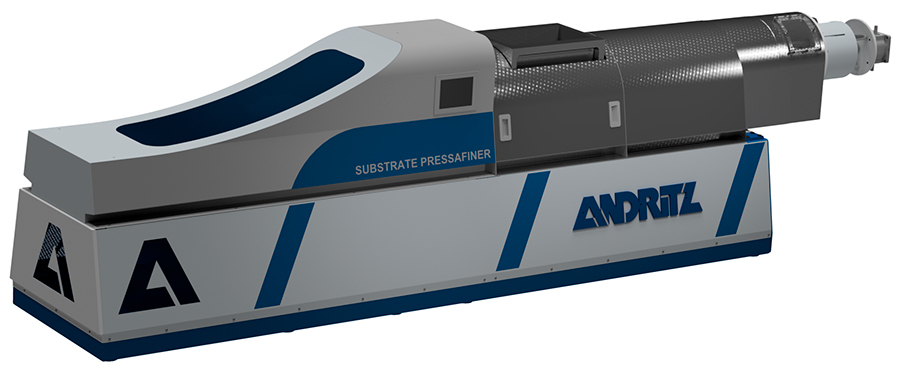

In case for a demand of medium to coarse fiber structures and especially for processing partially contaminated materials (e.g., with small stones and sand), we rely on the robust and slow-rotating new developed Substrate Pressafiner SP300 to fiberize wood chips.

Substrate Pressafiner SP300 – new development by ANDRITZ

Depending on the desired fiber structure and condition of available raw materials, we find the right solution to produce fiber substrates highly efficiently. Both machines are characterized by their ability to engineer fiber properties as needed.

Thomas Kaiser

Director, Wood Fiber Substrate

For more information:www.andritz.com/wood-fiber-substrate