- English

Bernhard Ostermann and Lukas Gutscher in front of the new ANDRITZ Substrate Refiner.

When the idea for the ANDRITZ Substrate Refiner first took shape, our engineering team knew it had to be more than just another machine—it had to be a solution tailored to the unique demands of the substrate industry. Today, after successful test run and impressive smooth functioning with extremely low vibration levels, we are proud to share the story behind its development.

“The goal was clear from the beginning,” says Bernhard Ostermann, Technical Director of the Engineering Department. “We wanted a machine that could handle a wide range of standard applications while offering the flexibility to switch between different demands for wood fiber production with simple and fast adjustments during production.”

With nearly 20 years of experience in refiner design and simulation, Bernhard led the technical development, applying advanced particle simulations to optimize key components like for example the direct feeder for the insertion of wood chips into the refiner casing.

Bernhard Ostermann during the test run of the new Substrate Refiner in ANDRITZ workshop in Graz.

Senior Designer Harald Kerner, with two decades of experience in pulp and paper machinery, was responsible for the mechanical design. “The challenge was integrating all main components into a compact, enclosed frame

that could withstand harsh industrial environments. We considered and evaluated several technical solutions belonging to ANDRITZ know-how, and we selected those which were the most suitable for the application”, Harald explains.

Designer Lukas Gutscher was responsible for the detail engineering and brought the concept to life by creating the digital model of the machine that combined the requirements which were set for this machine with an industrial design approach: focus was not only the aesthetics, but important aspects were functionality and maintenance friendliness. Additionally, he took care of producing stunning renderings for marketing, as well as the realization of 3D-printed models that amazed colleagues and trade show visitors alike. “Experiencing the evolution from concept to fully engineered machine and then finally seeing it built in our workshop was an incredibly rewarding experience”, Lukas shares.

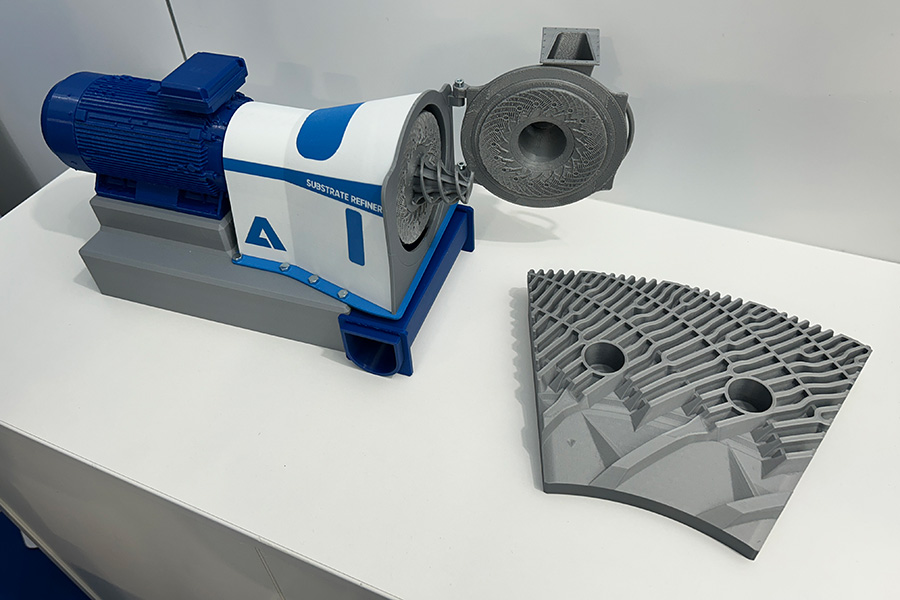

3D Models of ANDRITZ Substrate Refiner and ANDRITZ Quantum Refiner Plate exposed at the IPM Fair in Essen in January 2025.

Project Manager Alexander Uthoff followed the project development from the real beginning and explains: “The main challenges were the coordination between several colleges and a majority of tasks during the definition of the machine features, including constant follow up and adjustments of activities according to the new demands.”

In a second phase, once the final design was accomplished, Laurin Kment took over the project management to organize the manufacturing in our workshop: “There were of course some open points especially about costs and time frames. I am happy that everything worked very fine, and we achieved the wished targets as planned.”

From the outset, close collaboration with sales and product management ensured that customer feedback shaped every design decision.

The result? A refiner that combines proven ANDRITZ technologies with innovations tailored for substrate processing, like the modern, fast and very precise refiner gap adjustment and the latest advancement of the Swing Door opening.

This is not just a new machine. It’s the embodiment of engineering passion, customer insight, and decades of expertise melted together with the contributions of several colleges in a committed team.

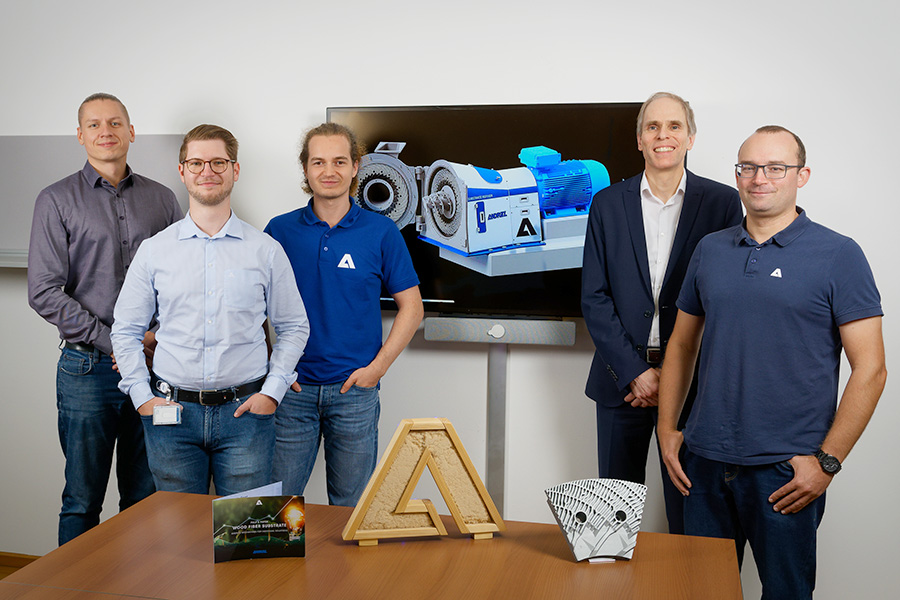

Core members of Engineering and Project Development team in ANDRITZ office in Vienna.

From left to right: Laurin Kment, Alexander Uthoff, Lukas Gutscher, Harald Kerner, Bernhard Ostermann.