- English

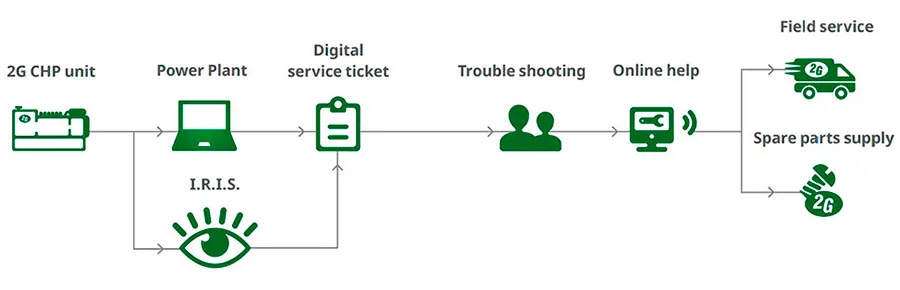

Identifying faults and malfunctions before they occur can increase plant availability. This is precisely the purpose of I.R.I.S, the Intelligent Report Information System, developed by 2G Energy. The system is the logical continuation of the 2G Power Plant software which automatically analyzes malfunction signals and triggers service incidents. However, even remote troubleshooting costs the plant operator both time and money. Predictive maintenance systems such as I.R.I.S. look to the future and allow operating irregularities to be detected quickly and avoid potential malfunctions or damages.

The software designed by 2G Energy constantly monitors plants for potential irregularities in operation. I.R.I.S. imports around 400 million sensor values every week and analyzes them. Thanks to cutting-edge realtime analyses and predictions, the results are available immediately. The comparisons and trend analyses collected by I.R.I.S. deliver insight information on the current operation and predictions for future plant behavior.

The system can also monitor plant operation over a longer period in order to better diagnose error patterns based on current and historic data. When I.R.I.S. detects an irregularity during operation, the software automatically sends all the relevant information and recommendations for action to the service team. I.R.I.S. is therefore a virtual assistant which is supported by experienced service colleagues.

The combination of machine and human intelligence helps to increase the level of remote maintenance, organize more efficient and on-demand on-site maintenance and avoid unscheduled downtimes – a real added value for plant operators. The use of I.R.I.S. requires no additional hardware for operators. An online connection is all that is needed to transfer sensor values. All customers, who use the 2G service via a service or maintenance agreement, can now profit from the “watchful eye” that I.R.I.S. has over your plants.