- English

Many horticultural businesses still use outdated IE1 motors without realizing the energy waste this causes. Old IE1 motors get the job done, but they are essentially the incandescent bulbs of greenhouse technology.

In modern greenhouses, crop production systems such as mobile container systems, conveyor belts, automated transport trolleys, stackers, lifting systems, packing lines, buffer conveyors and climate control systems including fans, screen systems, and irrigation installations operate 24/7 under demanding conditions. These processes are crucial for crop quality but often consume more energy than necessary. IE3 motors are now the standard, with the future focused on even more efficient options: IE4 and IE5 motors.

IE4: Premium Efficiency with Immediate Impact

The latest IE4 motors (super premium efficiency) consume up to 20% less energy than older models. For the average grower, this can save thousands of euros per year. Moreover, these motors are:

Did you know that only 3% of the Total Cost of Ownership (TCO) is the purchase price, while the vast majority is energy consumption?

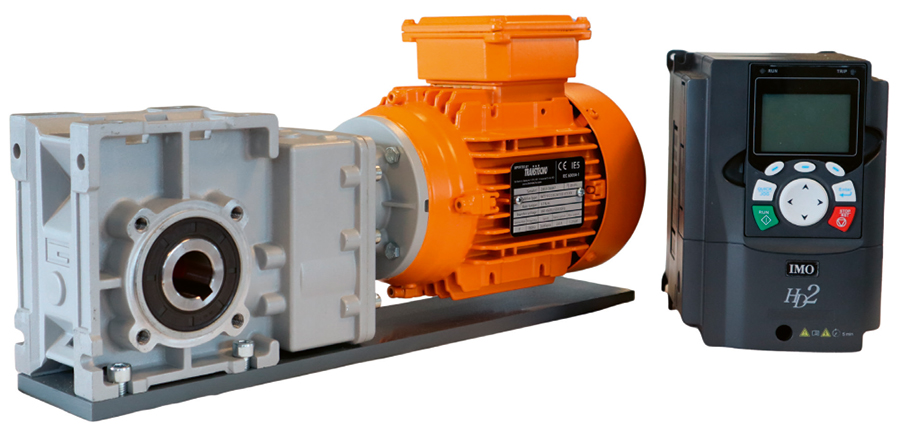

Maximize Savings by Combining IE4 Motors with Frequency Drives

Many greenhouse systems operate continuously at full power, even though actual demand fluctuates. By replacing outdated motors with IE4 models combined with frequency drives, speeds can be adjusted to meet real-time needs. The result? Even greater energy savings!

Curious About the Potential for Your Greenhouse?

Transtecno offers a free ROI calculation — contact us at info@transtecno.nl.