- English

Over 30 years ago, Polydress® LP-Keder celebrated its market introduc-tion. Since that time, the RKW Group has sold more than three million square meters of its innovative greenhouse film to nurseries and plant lovers around the world. Today, as in the past, our customers value the high transparency, thermal insulation, stability, and weather-proof quality of the easily installed air bubble film. Long-term studies have shown: Even after decade-long use, the greenhouse film manufactured by RKW offers optimal protection of the crops.

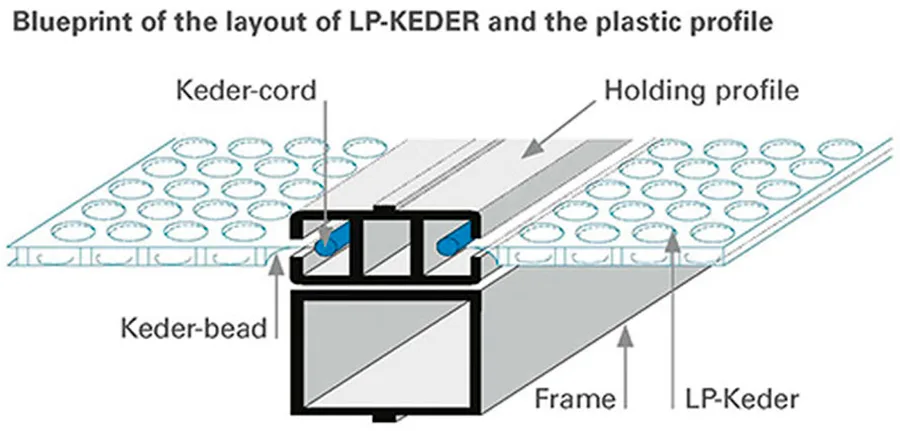

Investments made in R&D pay off: Based on experience, the globally lead-ing manufacturer of films and related technologies knows this. In 1984, RKW developed a new type of film construction for greenhouses. The development was completed in collaboration with the University of Hohenheim and the Reisinger Engineering Office in Illertissen. Three dec-ades later, Polydress® LP-Keder, which is manufactured from air bubble film, keder, and frame profile is used all over the world – from Europe to the Middle East; from North and South America to Asia and Australia.

Despite the elements

Whether in the snowy foothills of the Alps or in the hot climate of the Middle East – Polydress® LP-Keder manufactured by RKW stands for the highest level of weather protection for greenhouse films. During “Lothar,” the storm of the century that pounded southern Germany with wind gusts of up to 200 km/h in 1999, as well as in the devastating hailstorm that hit the Reutlingen region in August 2013, Polydress® LP-Keder was able to provide successful resistance and protection. While the golf ball-sized hail ripped huge holes into the glass roofs of the region’s greenhouses and thereby caused widespread damage to the crops, the hail only damaged the outer layer of the RKW film. The plants remained intact: The pro-duction and therefore the financial well-being of the nurseries was en-sured.

The resistance to hail was scientifically tested on the Polydress® LP-Keder greenhouse film by the Hail Research Laboratory in Reutlingen. The stan-dardized tests performed by the Hail Research Laboratory were based on the Swiss VFK (Swiss insurance) provisions for tent-like constructions and were conducted using 20-mm sized plastic “hail.”

The Polydress® LP-Keder easily withstood drop speeds of up to 17 me-ters/s. This meant, as per the standards, that the RKW greenhouse film is considered hail-resistant. Impact speeds of 30 meters/s and higher caused slight dents. However, after a short period of time, these formed back into their original condition. Once the hail reached speeds of 40 me-ters/s, the first layer of the film was perforated; from an impact speed of 47 meters/s the film was completely penetrated. Throughout the course of the tests, the hail-resistance of the Polydress® LP-Keder film was con-sistent across the film’s entire width. Due to its 1-mm thick keder-cord edge, the film’s most stabile part was the attachment connection. This was in stark contradiction to the simultaneously tested single-layer and 180 µm thick, standard PE film. This film was the most susceptible to hail damage at the attachment areas and in the outer edges. At impact speeds from 29 meters/s, the film exhibited dents and from speeds of 40 meters/s the film was perforated. While on the test bench at the Hail Research Laboratory, Polydress® LP-Keder displayed the perfect level of resistance against the hail.

Multiple stability

The experts agree: Due to the progressive change in our climate, in-stances of extreme weather are increasing. This means that, now more than ever, nurseries must optimally protect their most important re-sources – the young crops in the greenhouse – at all times; not only from hailstorms, but also from snow and high winds.

Although the greenhouse standard DIN 11535 does not require any spe-cial certificates related to the covering material, constructions up to four meters in height must be designed to withstand vertical wind gusts of 25 kp/m2 and over four meters wind gusts of up to 40 kp/m2. In terms of the snow load, greenhouses must be able to withstand a horizontal sur-face load of 25 kg/m2.

Whether Polydress® LP-Keder can also be used in these cases will be shown by a study conducted by the Institute for Agricultural Technology at the University of Hohenheim. For the material test, the test engineers constructed a wooden trough with a surface area of two-by-six meters and a height of 60 cm. They attached the film to the trough as would be the procedure for standard greenhouses. Using a powerful ventilator, the air was subsequently blown from the gaps and, in doing so, the film was uniformly burdened.

The factory new film remained fully intact during the test, even when it was subjected to the highest ventilator speeds. The film was able to with-stand surface loads of up to 236 kg/m2, which is several times higher than the stability required in practical use. However, how does film that has been subject to years of climatic influences react? In order to test this, the scientists removed an over 25-year-old Polydress® LP-Keder film from a greenhouse in Illertissen (at the Stauden Nursery Gaißmayer) and thoroughly tested it. The results speak for themselves: The weathered film survived both the maximal surface load as well as the additional con-centrated load of a person without sustaining any damage whatsoever.

Perfect light conditions for healthy growth

Both in practical use and in the test lab, the results were the same: Film covering materials such as Polydress® LP-Keder offer optimal protection – even under extreme climatic conditions, particularly when the growing of crops requires a high level of transparency and light. The approx. 1,000 air bubbles per m² provide uniform illumination of the entire cultivation space. The high degree of diffuse light eliminates shadows and burning glass effects. The optical laboratory in Wangeningen tested film samples from RKW in 2004 for the first time. During the tests, it was determined that the Polydress® LP-Keder film only lost a small portion of its transpar-ency, even after 17 years of use. In 2014 the results were again very positive: Despite enduring 25 years of sun, rain, snow, and ice, the film did not show any discolorations or clouding. The transparency remained almost uniformly high. The UR 2004 and 2014 transparency values of Polydress® LP-Keder (haze = light distribution) determined by the Optical Laboratory in Wan-geningen.

RKW guarantees five-years of UV stability for its air bubble film. With a heat transition value of 3.3 W/m2K, Polydress® LP-Keder also has optimal insulation properties and offers customers a high level of energy effi-ciency. The design made of air bubble film, keder, and profile prohibits leaks and thermal bridges so that the film can conserve up to 95 percent of the thermal radiation inside of greenhouses. A comparative test con-ducted at the Institute of Vegetable Gardening in Großbeeren that used two identically constructed greenhouses each measuring 10 x 50 meters showed that beneath the 4 mm-thick glass and a Polydress® LP-Keder film similar plant revenues were attained for both tomatoes and salad. Without humidity control, the energy savings using the RKW film totaled 44 per-cent for salad and 27 percent for the tomato plants.

Simple installation regardless of the weather conditions

Apart from the energy costs, Polydress® LP-Keder also significantly lowers the time and effort that the nurseries must exert for the installation or maintenance of their greenhouses. Through the attachment of the keder and its low weight, the film can be installed from the pitched roof or side walls.

The structure’s roof doesn’t have to be accessed; this increases the safety and simplifies the installation process. This means that the film is simply taken from the roll, fed into the frame profile, pulled to the desired end point towards the top, and then cut off using a knife or a scissors. Old or defect lengths of film can easily be replaced during any kinds of weather conditions. This keeps the costs low and makes a direct contribution to sustainability. RKW’s polyethylene greenhouse film can be completely recycled or thermally processed further.

Additional information regarding the Polydress® LP-Keder greenhouse films and their range of applications can be found at www.rkw-group.com.