- English

When investing in a new greenhouse or upgrading existing propagation facilities, growers today face a clear set of priorities: achieving consistent crop quality, reducing labour dependency, and complying with growing environmental requirements. The Growcoon, a fully biodegradable propagation plug, offers a reliable, proven path forward — enabling growers to build with confidence, produce with efficiency, and scale sustainably.

Strong rooting, less transplant loss, faster cycles

The Growcoon has proven itself across a wide range of crops and substrates. Its flexible, open mesh structure supports the development of a uniform and stable root ball, which enhances transplant success and reduces loss rates. By promoting faster and more homogeneous rooting, Growcoon also enables earlier transplanting and shorter cultivation cycles. For nurseries operating under high turnover and tight delivery windows, this provides a significant increase in productivity without additional surface area.

Growcoon in action – reliable rooting across crops, stages and systems.

„Last year our Lonicera Nitida Elegant, 1.5 litre pots sold out quickly. Growcoon saves several weeks of time per cultivation cycle, allowing us to easily set up a second round. And that, of course, offers perspective,“ explaines Patrick Damen, Owner of Damen Nursery.

Growcoon plugs are available in a wide range of standard sizes and can be customised to fit specific tray formats and propagation systems. They are compatible with all common cultivation methods — from sowing and cuttings to hydroponics and vertical farming. The material is TÜV-certified, fully biodegradable and free from PFAS. No residues remain in the tray or substrate, and no synthetic waste enters the environment.

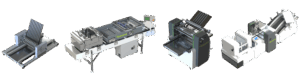

Automation-ready: semi and fully automatic dispensers available

Labour-saving potential is another key benefit. With seasonal labour becoming harder to secure, Growcoon helps growers maintain productivity without increasing staff numbers. In combination with semi- or fully-automated dispensers, propagation tasks can be completed more quickly and with higher precision. This allows skilled labour to be focused where it matters most, while the system ensures consistent results across batches.

Jelle Broeders, Director Van der Avoird Trayplant points out: „Because in the Growcoon every plant becomes a well-rooted plug, we can sort 100% automatically. This brings enormous labour savings. More importantly, we think it allows us to deploy our employees sustainably and offer them a pleasant working environment and better working conditions.“

“The demand for higher cultivation capacities continues to rise,” adds Raymond van Ispelen, Product Manager at Klasmann-Deilmann. “The new dispenser series offers a precise and scalable solution that increases operational capacity while reducing dependence on scarce manual labour.”

Picture Caption: From manual to fully automatic – streamline your processes with Growcoon dispensers

From an economic standpoint, Growcoon supports a smarter use of resources. It helps to reduce waste, avoid costly replanting, and increase the number of successful plants per square metre. The system fits seamlessly into existing tray formats and substrates, meaning growers can test and implement it without major operational changes.

Klasmann-Deilmann supports growers throughout the implementation process with technical advice, tailored trial kits, and integration support. This ensures that the system performs reliably from the first cycle — and scales with the needs of the nursery.

Download the Growcoon brochure:

https://klasmann-deilmann.com/wp-content/uploads/Growcoon_brochure_EN_04_25.pdf

Request a free trial kit for your crops:

Request your free trial kit | Growcoon