- English

Whole milk feeding is becoming increasingly important in calf rearing. However, there are a few technical obstacles to be overcome for feeding at the calf feeder. There has to be a constant supply of milk in the storage tank, for example, because the calves come to feed all day long. But if the calves feed more than usual, the tank is empty too quickly and the animals do not get any milk for a certain time.

On the other hand, there is often some milk still left in the tank when it is to be filled and cleaned. This is often simply thrown away. Since this is expensive, however, the fresh milk is often just added to the old milk in the tank and feeding continues without the storage tank being cleaned properly.

In addition, conventional milk tanks start to freeze over when the level in the tank is very low, which is a problem. It damages the milk and puts a strain on the technology. For this reason, we have developed the ultimate solution for you for the storage of whole milk for calf feeders like the CalfExpert. Learn how the DoubleJug solves all of the above problems here.

Feed whole milk for 24 hours – and refill when it suits you

The CalfExpert calf feeder draws its milk from one of the tanks. Should this tank become empty, the DoubleJug switches automatically to the second tank and the CalfExpert can continue to feed without interruption. This means no waiting times and no interruptions in feeding, thus making optimum use of the CalfExpert’s high performance.

Once a tank has been cleaned, DoubleJug is ready for filling. Usually both tanks are filled to take advantage of the maximum capacity of the DoubleJug. The advantage of the two-chamber system is that the DoubleJug can be filled at any time without having to wait for the exact moment the milk tank is empty. There are neither residual quantity nor times during which the CalfExpert stops feeding due to lack of milk.

Control through the CalfExpert

The DoubleJug is controlled via the CalfExpert and programmed at the feeder display. This allows the tank status to be viewed directly at the feeder as well as in CalfGuide at any time. An information unit can be fitted to the DoubleJug as an option that displays the most important information such as temperature, fill level etc. directly in the barn.

It also includes automatic cleaning: as soon as the first tank is empty, it is cleaned automatically. This means maximum hygiene and best milk quality. The cleaning cycles are coordinated by direct communication with the CalfExpert. Thus the daily cleaning of the milk line between the DoubleJug and the CalfExpert only takes place when the milk tank itself is being cleaned. This minimises any waiting times for the calves.

Room in every hutch for cool stuff

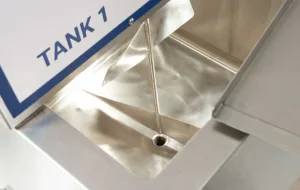

The tank does not take up much space in the calf barn thanks to its angular design. This means it can be positioned close to the calf feeder.

The DoubleJug is equipped with a cooling unit for both tanks. Even small amounts of milk are cooled efficiently without freezing.

More information: www.holm-laue.com