- English

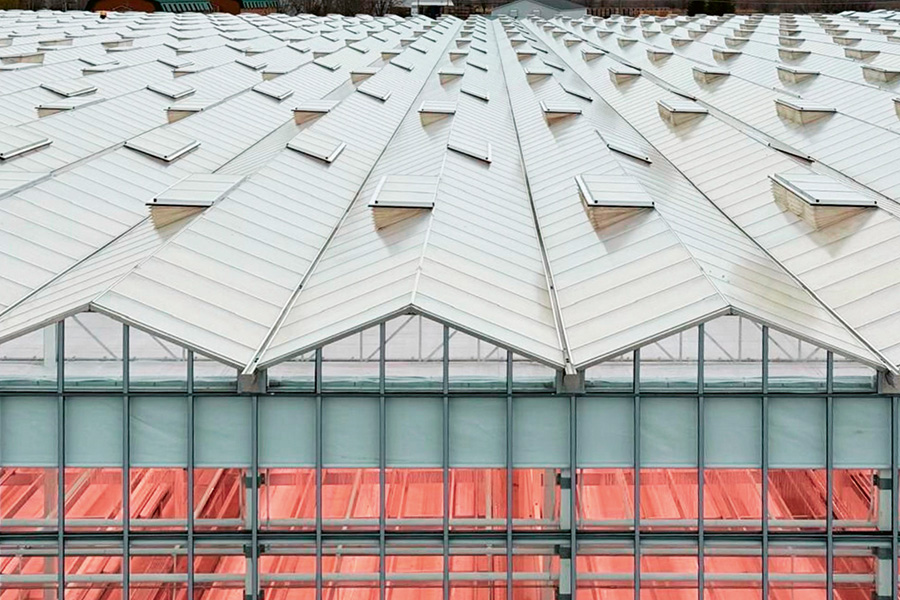

At the core of the Vermax glass greenhouse is Harnois’ patented energy management system—entirely deve-loped in Canada and manufactured locally. This homegrown innovation meets the demanding standards of Nearly Zero Energy Buildings (NZEB), helping growers significantly reduce their environmental footprint while optimizing operational efficiency.

Built on a semi-closed greenhouse model, the system combines passive design strategies with a modular thermal energy platform. Its plug-and-play design connects easily to thermal recovery projects and delivers a peak Coefficient of Performance (COP) of up to 7.5—making it one of the most energy-efficient systems available today.

The technology also includes a circular water management loop that recycles all irrigation water, eliminating wastewater and reducing the need for additional water intake after the initial launch—a true step toward zero-wastewater agriculture.

Vermax further integrates a closed-loop CO2 enrichment system that captures CO2 from ambient air, concentrates it, and redistributes it into the crop zone. It eliminates the need for external CO2 sources while enhancing plant growth. Together, these innovations contribute to a 70% reduction in greenhouse gas emissions compared to traditional greenhouse operations.

Harnois’ energy management platform is fully designed, tested, and built in Canada, ensuring it’s tailored to North American climates and growers. More than just a greenhouse, Vermax is a fully integrated climate and energy solution for sustainable food production.

This breakthrough technology is already having a significant impact. Harnois recently completed a 5.2-hectare Vermax project with VegPro International, supporting year-round production of leafy greens. This large-scale, carbon-conscious facility is a powerful example of how Canadian innovation can lead the way toward climate-smart, energy-responsible agriculture.