- English

ETW Energietechnik from Moers presents a valuable addition to the ETW SmartCycle® and ETW SmartCool® series. ETW‘s biogas upgrading system, which is used worldwide, is known for the lowest energy consumption of all upgrading processes on the market. In times of rising energy prices, there are therefore very significant advantages for plant operators who have opted for ETW‘s biogas upgrading system.

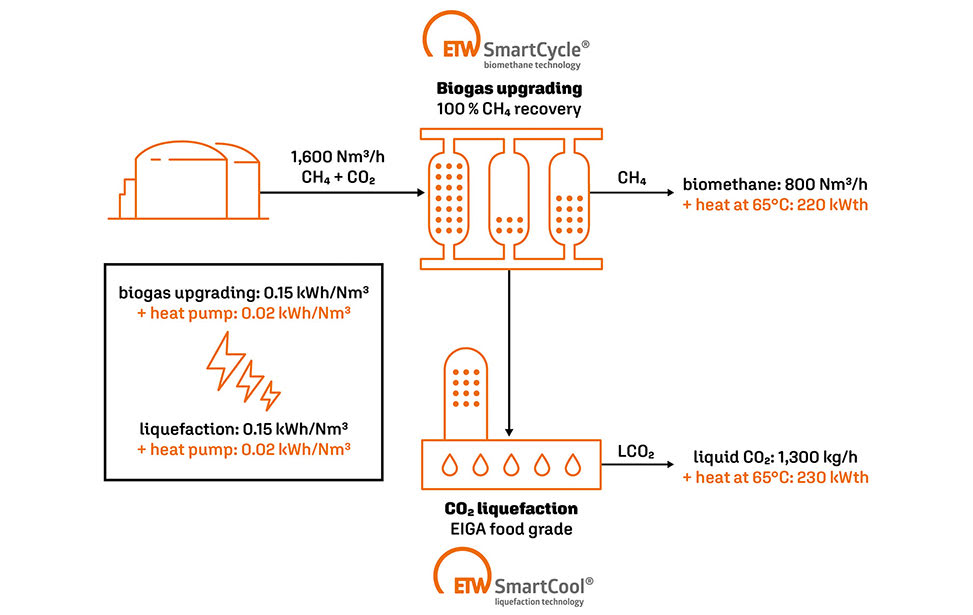

For example, an ETW SmartCycle® L plant with a biogas upgrading capacity of 1600 Nm³/h raw biogas consumes around 0.15 kWhelectric/Nm³. However, due to the energy-optimised ETW plant design, very little waste heat is generated at a usable temperature level.

Heat supply increases production costs

Often, the valuable biogas is then used for additional heat production on site, reducing the biomethane productivity and potential profit.

Heat pump ensures higher profitability

To enable these operators to achieve higher profitability, the ETW SmartCycle® biomethane plant can now be equipped with a heat pump. This means that with a low additional electrical consumption, a significant amount of useful heat can be decoupled at a temperature level >65°C.

Also the ETW Smart Cool® LCO2 liquefaction plant can be upgraded with a heat pump. In the example described above (with heat pump, see sketch), a thermal output of up to 220 kWthermal at 65°C can be provided, or even up to 450 kWthermal when coupled with the CO2 liquefaction plant.

Improved energy balance, more flexibility

The electricity consumption of the biogas upgrading plant is increased from approx. 0.15 to approx. 0.17 kWh/Nm³ raw biogas by adding the heat pump. This is still about half compared to alternative upgrading technologies. By adding efficient heat pump technology, ETW Energietechnik GmbH thus enables many operators to achieve an even better energy balance with increased flexibility.

Click here for more company information!